Sample SOP for MS in Mechanical Engineering [With work experience]

Sample SOP for MS in Mechanical Engineering: From my earliest memories, I’ve been captivated by the inner workings of various mechanisms, whether it was disassembling and fine-tuning my bicycle or conceptualizing a lift model for a science exhibition. My inquisitiveness was consistently focused on understanding the operations of devices. Encouraged by my parents, teachers, and my inherent affinity for science and technology, pursuing a degree in mechanical engineering seemed the natural and fitting career path for me.

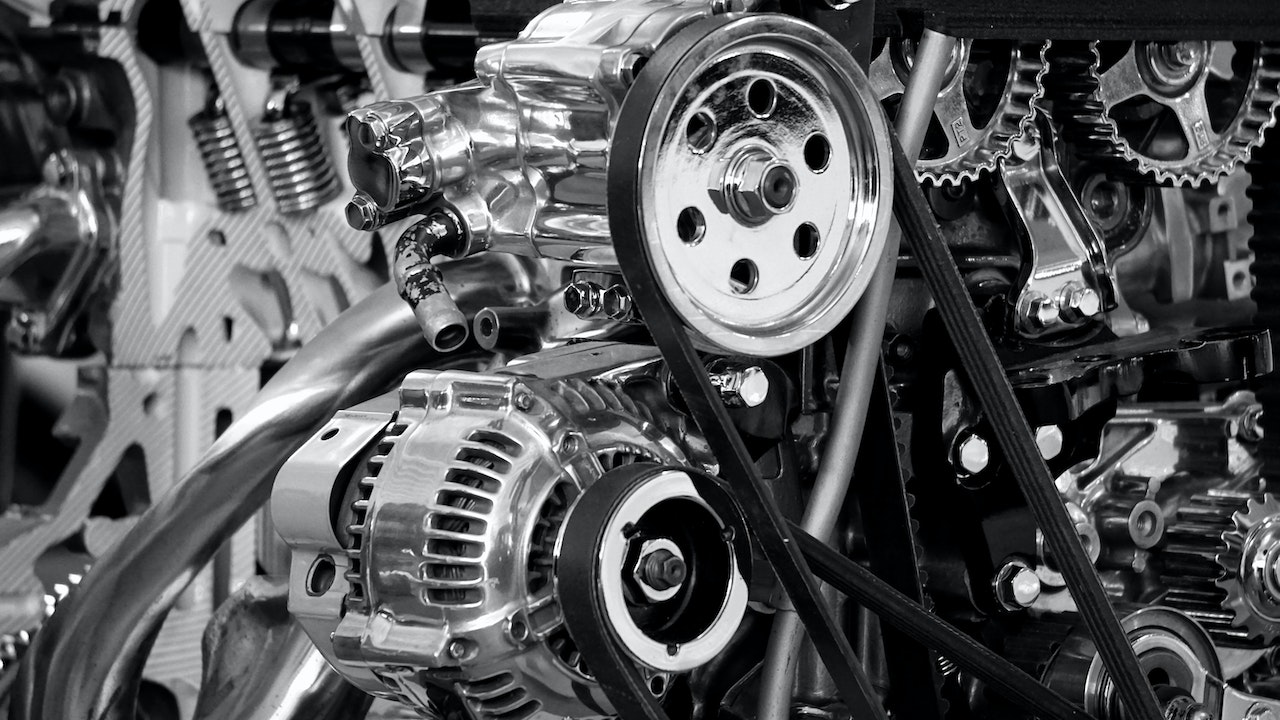

My undergraduate program was a judicious mix of theory and practice. Fascinating subjects like Operation Research, Engineering management, Automobile engineering, Total Quality Management, Process planning and cost estimation, Marketing management and Advanced IC engines — compelled me to seek extended knowledge outside the realm of my syllabus. These not only enhanced my learning but also reflected in my excellent academic grades.

During my academic journey, I took on projects that not only honed my fundamental skills but also allowed me to explore my deep-seated interest in utilizing alternative fuel sources for environmental conservation. This passion was amplified during my pre-final project, where I devised a pressure burner utilizing blended ethanol. I crafted a prototype that replicated the functionality of an actual burner without physical fabrication, designed to accommodate the use of sugar bagasse—an alternative but highly viscous fuel with a high ignition point. This endeavor garnered praise from my department and earned me a commendable score of 93%. The project even secured a nomination among the top three for the Best Project Award. Additionally, I engaged in in-plant training at Hi-Tech Bearings Enterprises, a renowned manufacturer of automotive bearings, bushings, and thrust washers. Here, I was exposed to various manufacturing processes, including the automation of batch processing on the production line, leading to significant time and cost savings. It was during this experience that I witnessed the seamless synergy of Operations Research and Lean Manufacturing techniques in establishing an efficient production system, sparking an immediate fascination for this area. Furthermore, I successfully completed in-plant training at TechPro Engineering Co, a prominent CNC manufacturing company in India. This opportunity provided me with valuable insights into diverse manufacturing systems, such as lathe bed manufacturing, employing a robust vertical 5-axis machining center manufactured by L&T. Visits to leading industries in India including TATA Group, Kirloskar, Godrej Group, Larsen and Toubro, Thermax, among others, further enriched my understanding of group technology, cellular manufacturing, and MRPII, offering invaluable real-world exposure in the industry.

Sample SOP for MS in Mechanical Engineering || Best coaching for GRE

Although my experiences up to that point had convinced me of the importance of pursuing higher education in this field, an offer to gain valuable hands-on experience in Mechanical Engineering presented itself when I had the opportunity to work with BPL Global. The focal point of my role was the mathematical modeling of power plants. In this dynamic environment, I became an integral part of a diverse team consisting of domain specialists, software developers, and project managers. This exposure acquainted me with various modeling challenges, optimization strategies, and diagnostic techniques. The products and services I directly contributed to in terms of design and implementation included Economic Dispatch, plant performance monitoring, and alarm analysis. It was during my tenure in this domain that I gained a profound appreciation for the potential impact of Operations Research on enhancing the performance and revenue of industrial processes.

The deliverables that I worked on during my stint were implemented in many power plants across India and Middle East, including BHEL plants through renowned OEM’s like ABB India Ltd. The product knowledge and services I have rendered to these customers helped me carve a niche for myself. I also used my software skills in VB6, Java and UML effectively to design some of the delicate algorithms. With the techno-functional expertise I gained over a period of time, I successfully reviewed the codes and honed the products.

Sample SOP for MS in Mechanical Engineering || Best coaching for GRE

I also completed a company-sponsored ISO 9001:2000 Internal Auditor training program conducted by SCRAM Systems. I excelled in conducting numerous internal audits, earning the distinction of being named the Best Internal Auditor for the period of 2012-2014. My keen analytical abilities and comprehensive understanding of processes led to my appointment as the process owner for products. I was given the opportunity to assist in shaping and defining the organizational structure and processes alongside the Management Representative.

During this time, I recognized the importance of incorporating the latest optimization and decision-making techniques into my skill set. This drove me to pursue further education in Mechanical Engineering. I am particularly interested in focusing on practical applications of Operations Research and Supply Chain Management. Topics like process optimization, supply chain modeling and analysis, decision processing, numerical optimization, and stochastic processes and probability are areas I aim to delve into. Considering Purdue University’s wealth of resources and the presence of world-class faculty engaged in the program, I believe it is the perfect fit for my aspirations.

With a Bachelor’s Degree in Mechanical Engineering, coupled with industry-related experience and expertise in optimization solutions, as well as a background in project management, I am confident in my ability to thrive in a Postgraduate Mechanical Engineering program. Following my master’s degree, I aspire to collaborate with a research and development team, contributing to the advancement of technology. I sincerely hope you will consider my application, and I would be honored to become a part of your esteemed institution.

We are a platform that connects aspiring candidates with experts who have aced the admission process at the top universities of the world. We offer highly personalized programs at the most affordable market beating prices. You can fill the form below for any help or guidance with your application in general or scholarships in particular. Alternatively you write to us at connect@careercarta.com

Sample SOP for MS in Mechanical Engineering [Without work experience]

Sample SOP for MS in Mechanical Engineering: From my earliest memories, I’ve been captivated by the inner workings of various mechanisms, whether it was disassembling and fine-tuning my bicycle or conceptualizing a lift model for a science exhibition. My inquisitiveness was consistently focused on understanding the operations of devices. Encouraged by my parents, teachers, and my inherent affinity for science and technology, pursuing a degree in mechanical engineering seemed the natural and fitting career path for me.

My undergraduate program was a judicious mix of theory and practice. Fascinating subjects like Operation Research, Engineering management, Automobile engineering, Total Quality Management, Process planning and cost estimation, Marketing management and Advanced IC engines — compelled me to seek extended knowledge outside the realm of my syllabus. These not only enhanced my learning but also reflected in my excellent academic grades.

During my academic journey, I took on projects that not only honed my fundamental skills but also allowed me to explore my deep-seated interest in utilizing alternative fuel sources for environmental conservation. This passion was amplified during my pre-final project, where I devised a pressure burner utilizing blended ethanol. I crafted a prototype that replicated the functionality of an actual burner without physical fabrication, designed to accommodate the use of sugar bagasse—an alternative but highly viscous fuel with a high ignition point. This endeavor garnered praise from my department and earned me a commendable score of 93%. The project even secured a nomination among the top three for the Best Project Award. Additionally, I engaged in in-plant training at Hi-Tech Bearings Enterprises, a renowned manufacturer of automotive bearings, bushings, and thrust washers. Here, I was exposed to various manufacturing processes, including the automation of batch processing on the production line, leading to significant time and cost savings. It was during this experience that I witnessed the seamless synergy of Operations Research and Lean Manufacturing techniques in establishing an efficient production system, sparking an immediate fascination for this area. Furthermore, I successfully completed in-plant training at TechPro Engineering Co, a prominent CNC manufacturing company in India. This opportunity provided me with valuable insights into diverse manufacturing systems, such as lathe bed manufacturing, employing a robust vertical 5-axis machining center manufactured by L&T. Visits to leading industries in India including TATA Group, Kirloskar, Godrej Group, Larsen and Toubro, Thermax, among others, further enriched my understanding of group technology, cellular manufacturing, and MRPII, offering invaluable real-world exposure in the industry.

For my final year project I worked on Design and Optimization of a Variable Geometry Turbocharger for Automotive Applications with professor Mukherjee. Its primary goal was to develop a turbocharger system that dynamically adjusts its geometry to optimize engine performance across a wide range of operating conditions. This entails a meticulous process, starting with a comprehensive examination of existing turbocharger technologies and their limitations. A conceptual design was then formulated, taking into account factors such as aerodynamic principles, material selection, and manufacturing feasibility. Advanced computational fluid dynamics (CFD) simulations are employed to model the airflow dynamics within the turbocharger, enabling precise analysis of pressure ratios, velocity profiles, and temperature distributions. These simulations served as a critical guide throughout the optimization process.

Furthermore, the project involved the intricate task of developing a variable geometry mechanism, encompassing components like actuator systems, vanes, and linkages. This mechanism was instrumental in providing precise control over the turbocharger’s geometry, a pivotal aspect of its functionality. Rigorous material selection and structural analysis were undertaken to ensure that all components can withstand the demanding operating conditions within an automotive engine. With the components designed and analyzed, the project moves to the manufacturing phase, where advanced techniques like additive manufacturing (3D printing) and precision machining were employed. These techniques were utilized to fabricate the components, which were then assembled into a functional prototype. Subsequently, the prototype undergoes extensive testing on a dedicated testbed, allowing for a comprehensive assessment of its performance under various engine loads and speeds. Data collected from these tests was thoroughly analyzed to validate the turbocharger’s efficiency gains and to ensure it meets the project’s objectives. The anticipated outcome of this project was a groundbreaking advancement in automotive engine technology, with the potential to significantly enhance engine efficiency, power output, and fuel economy, particularly in scenarios involving transient loads or variable engine speeds. Ultimately, this endeavor exemplifies the remarkable potential of mechanical engineering in advancing automotive technology towards greater sustainability and efficiency.

During this time, I recognized the importance of incorporating the latest optimization and decision-making techniques into my skill set. This drove me to pursue further education in Mechanical Engineering. I am particularly interested in focusing on practical applications of Operations Research and Supply Chain Management. Topics like process optimization, supply chain modeling and analysis, decision processing, numerical optimization, and stochastic processes and probability are areas I aim to delve into. Considering Purdue University’s wealth of resources and the presence of world-class faculty engaged in the program, I believe it is the perfect fit for my aspirations.

With a Bachelor’s Degree in Mechanical Engineering, coupled with industry-related experience and expertise in optimization solutions, as well as a background in project management, I am confident in my ability to thrive in a Postgraduate Mechanical Engineering program. Following my master’s degree, I aspire to collaborate with a research and development team, contributing to the advancement of technology. I sincerely hope you will consider my application, and I would be honored to become a part of your esteemed institution.

We are a platform that connects aspiring candidates with experts who have aced the admission process at the top universities of the world. We offer highly personalized programs at the most affordable market beating prices. You can fill the form below for any help or guidance with your application in general or scholarships in particular. Alternatively you write to us at connect@careercarta.com

Sample SOP for MS in Mechanical Engineering

Read about: SOP Writing Services

Read more about: Sample SOP for MS

Read more about:Sample SOP for MS in Chemical Engineering

Read more about: Sample SOP for MS in Electrical Engineering

Read more about: Sample SOP for MS in Cybersecurity

Read more about: Sample SOP for MS in IOT

Read more about: Sample SOP for MS in Blockchain

Read more about:Sample SOP for MS in Computer Science

Read more about:Sample SOP for MS in Computer Architecture

Read more about: Sample SOP for MS in Artificial Intelligence

Read more about: Sample SOP for MS in Civil Engineering

Read more about: SAMPLE SOP FOR CHICAGO HARRIS SCHOOL OF PUBLIC POLICY-Selected Candidate

Read More About: Canada Scholarships